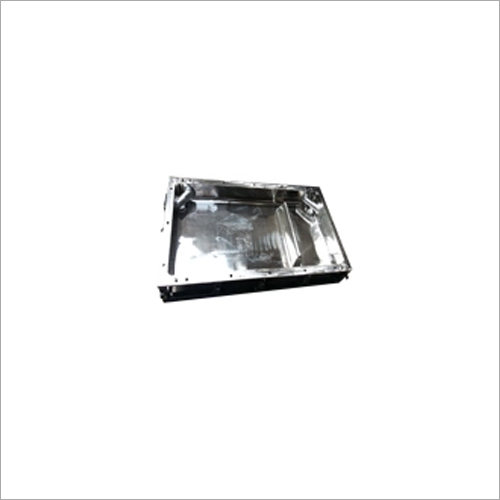

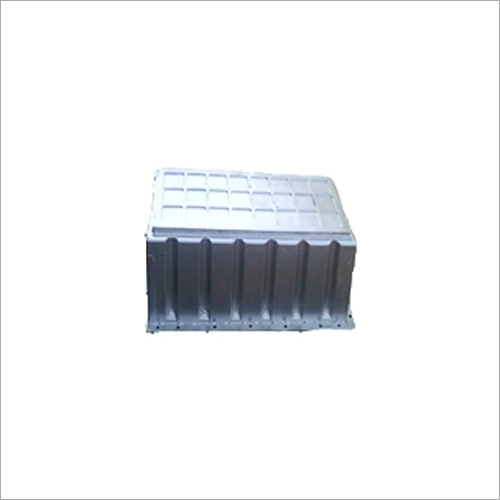

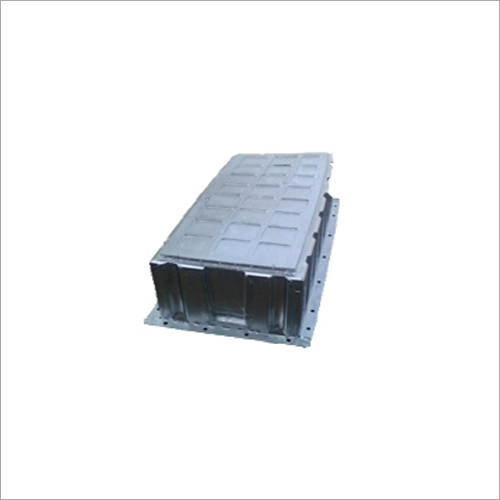

Plastic Crate Mould

Product Details:

- Usage Industrial

- Product Type Plastic Crate Mould

- Material Plastic

- Shaping Mode Die Casting

- Click to View more

X

Plastic Crate Mould Price And Quantity

- 1 Piece

Plastic Crate Mould Product Specifications

- Plastic Crate Mould

- Die Casting

- Plastic

- Industrial

Plastic Crate Mould Trade Information

- Cash in Advance (CID)

- 20 Piece Per Week

- 15-20 Days

- All India

Product Description

With Plastic Crate Mould, the custom plastic parts come out hollow and thin-walled. When the plastic part needs to have a homogeneous wall thickness, this approach is ideal. It is very similar to the process of glass blowing. When the raw plastic is heated enough to become liquid, the machine inflates it with air like a balloon. The plastic is blown into a Plastic Crate Mould and as it gets bigger it presses against the mold walls and it starts to take its shape.

Enter Buying Requirement Details