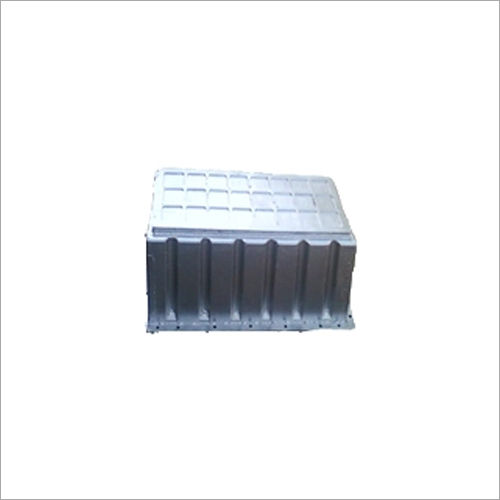

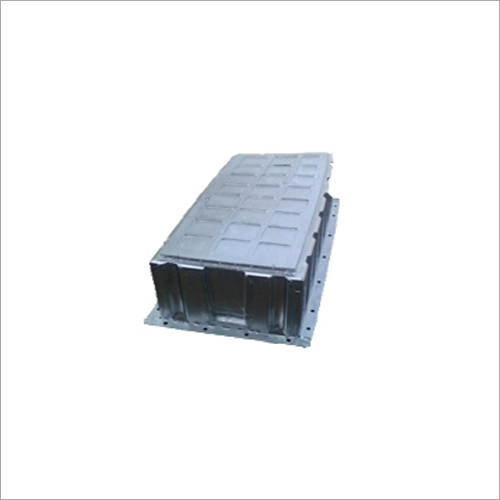

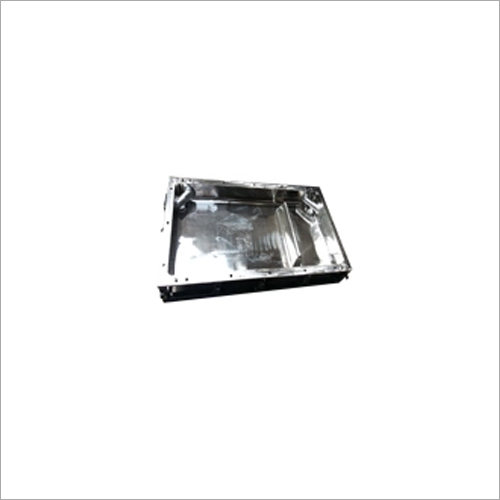

Crate Mould

Product Details:

- Usage Industrial

- Product Type Crate Mould

- Material Plastic

- Shaping Mode Die Casting

- Click to View more

X

Crate Mould Price And Quantity

- 1 Piece

Crate Mould Product Specifications

- Crate Mould

- Plastic

- Industrial

- Die Casting

Crate Mould Trade Information

- Cash in Advance (CID)

- 20 Piece Per Week

- 15-20 Days

- All India

Product Description

The material for the part is fed into this Crate Mould and mixed using a helical shaped screw. Heating bands melt the material in the barrel and the molten metal or molten plastic material is then fed into the mold cavity where it cools and hardens, matching the shape of the mold. The cooling time can be reduced through the use of cooling lines that circulate water or oil from an external temperature controller in the Crate Mould.

Enter Buying Requirement Details