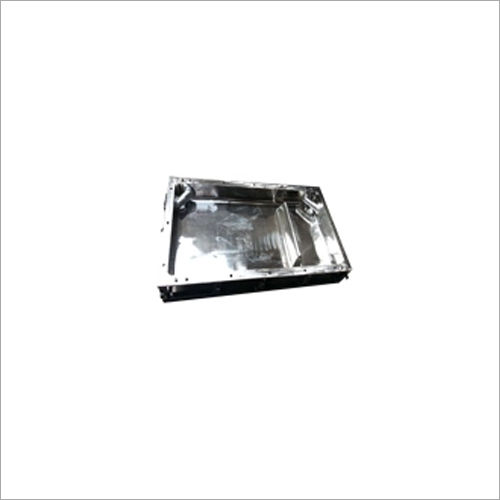

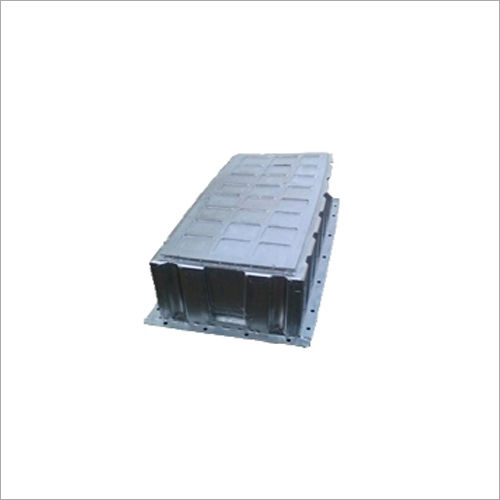

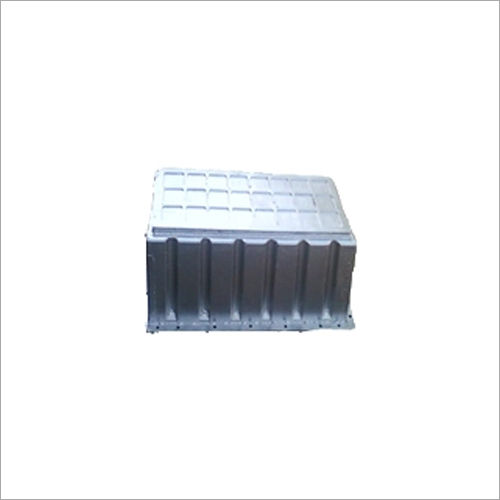

Avail from us a wide range of high-quality Custom Plastic Tank Mold, Customized Plastic Bin Molds, Crate Mould, Custom Crate Mould, Plastic Bin Molds With Lid, and more.

Shree Sai Roto Plast, is working from Kapadwanj, Gujarat, India as a renowned Manufacturer and Supplier of a wide range of quality products such as Customized Icebox Molds, Customized Plastic Dustbin Molds, Plastic Pulverizer, Rotomolding Machine, Plastic Car Tank Dies, Plastic Crate Mould, and more. Our products are engineered with high-grade raw materials with advanced technology for high accuracy. Our products are known for hassle-free usage, excellent performance, and high durability.

We have a pattern making room, wherein a team of professionals designs the range using table saw, disc sander and planner machine. The room is backed with the facility of die casting, AutoCAD, and mould building. It helps us in designing qualitative range in different sizes, specifications and configurations.

We have a pattern making room, wherein a team of professionals designs the range using table saw, disc sander and planner machine. The room is backed with the facility of die casting, AutoCAD, and mould building. It helps us in designing qualitative range in different sizes, specifications and configurations.

With the high quality of our products, we aim to acquire complete customer satisfaction. To fulfill the vision, we also rely on our timely delivery of products and quotation of competitive prices. The on time deliveries are ensured via the assistance of a wide distribution network and punctual transportation support. Along with this, we quote competitive cost for the bulk orders that makes us the favorite of clients based in different parts of India.

Quality Assurance

Quality is one of the major aspects that helps us in maintaining our well-known position in the market. This also helps us in attaining maximum satisfaction of the clients as we always stand by their expectations. For this, our finished products are checked on various parameters for their unparalleled performance. Some of the parameters on which we test our products are as follows:

- Strength

- Elongation test

- Hardness

- Durability

Areas of Application

Our array of products like Custom Plastic Tank Mold, Customized Plastic Bin Molds, Crate Mould, Custom Crate Mould, Plastic Bin Molds With Lid, and more is used in various applications. Because of their features like high strength, durability, ease of mold, and more they are used for making numerous products. Some of the major products made out of our gamut are buckets, bumpers, food trays, containers, chemical tanks, trolleys, swimming pools, and so on. Some other products that are developed from our range are:

|

|

Our Roto Moulding Process

There are three primary processes carried out in the plastic industry such as extrusion, blow molding and injection molding. However, these processes carry a few disadvantages because of which Rotational Moulding has become one of the most favorable choices. The heating and cooling in this process is carried out in a mold. This process is carried out in the absence of pressure (at ambient pressure) to withstand environmental stress and cracks.

A cold mold is used for placing the specific amount of blended Polyethylene Resin Powder. In the oven, this mold is rotated and heated. With heating, the resin powder begins melting which results in good coating of molten resin along side the inside surface of mold. At the end of this stage, the mold gets transferred to the cooling chamber wherein the molds stay in rotating position. The continuation of this bi-axial rotation goes on until the cooling processes and solidification of the polyethylene.

Some of the advantages of this process are as follows:

- One-piece construction

- Can produce multi-wall Mouldings

- Minor undercuts

- Excellent load-bearing properties

- Resistance to corrosion

- Uniform wall thickness

- Comes in a variety of finishes and colors